Although engineered wood — such as plywood or particle board — is great for a range of building and manufacturing uses, it has its limitations, especially in outdoor applications. One of the biggest limitations is not the wood, but the adhesive used to glue the wood veneers or particles together. These adhesives are one of the most significant costs in manufactured wood products.

Scientists at the USDA Forest Service are partnering with researchers at Oregon State University, Argonne National Laboratory, and Scion — a New Zealand research lab — to better understand what controls performance at the “bond line,” or where the adhesive meets the wood. To accelerate the development of new and improved wood adhesives for engineered wood products, the group is working to understand the optimal adhesive penetration for specific products and applications.

“The key to developing new and improved wood adhesives, especially for moisture durability, is for scientists to have a better understanding of how an adhesive penetrates the wood,” said Chris Hunt, a Forest Service research chemist at the Forest Products Laboratory. “We investigated both the flow of adhesive into microscopic voids in the wood’s structure and infiltration into the wood’s cell walls.”

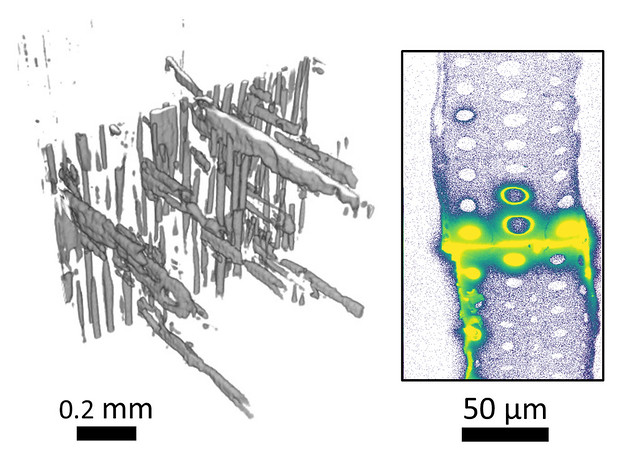

Scientists test how well a piece of plywood or product will perform in a real-life situation by putting the product through several wet-dry cycles to mimic outdoor conditions. Wood swells when wet and contracts when dry, testing the strength of the wood-adhesive bond. While changes like these are visible to the naked eye, observing these changes at smaller scales requires advanced imaging tools, such as X-ray computed tomography, X-ray fluorescence microscopy, and small angle neutron scattering to study the way the adhesive flows into air spaces in the wood structure, then enters cell walls, especially beneath the wood’s surface.

Researchers found that smaller adhesive molecules are more effective than larger molecules at entering the cell walls and minimizing the effects of moisture on the properties of the wood nearest the bond line. Additionally, research results have helped scientists identify the most important interactions between adhesive and nanoscale cell wall structures for creating moisture-durable wood adhesive bonds.

“We expect that understanding how adhesives work in wood will lead to better products at a lower cost,” said Hunt. “Wood products are renewable, support rural communities and remove CO2 from the atmosphere. Making them more competitive is good for business and for the environment.”